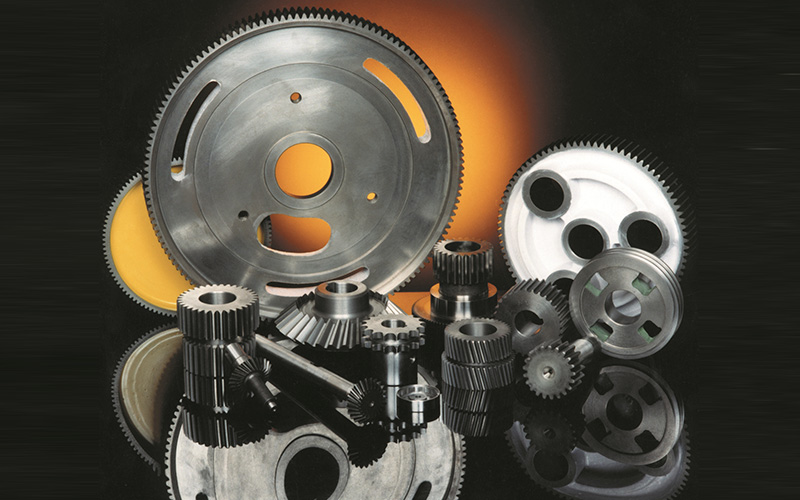

Gears

Gear drives are the most versatile and accurate form of drive. They can transmit drive at any angle, any speed and practically at any load conditions. Accurate transmission of speed, maintaining constant pressure angle and smooth running of gears are achieved by high tech manufacturing of gears. Carefully chosen raw material ensures longest life or the gear.

Modern Process

Thanks to the CNC laths with which quality standards like uniform closer tolerance, tooth accuracy, trueness and repeat-ability has become a reality, meeting international standards. Fully automatic system like turning, broaching, drilling, tooth cutting, shaving, grinding, hardening and honing are all the processes where gears are crafted. Special surface treatment like HF hardening / case hardening / nitrating enhances wear resistance.

Applications

Spur / Helical – Blowroom to Ringframe

Timing belt Pulley – All machines

Sprocket wheels – All machines

Bevel – All machines

Worm and Worm wheels – All machines

Planetary gears – Drawframe, Comber and Speedframe

Ratchet wheel – Combing machines

Inspection System

- Gears are tested at dedicated climate controlled gear lab with master gears forevery profile using sophisticated testing equipment like profile testers and doublelank testers.

Benefits

- Lead quality

- Interchangeability

- Reliability

- Extended life

info@lmwtmd.com

info@lmwtmd.com