Gimatex Success Story

LMW and Gimatex

The long-standing partnership between LMW and M/s. Gimatex for over three decades has not only weathered the tests of time but has also evolved with the changing dynamics of the industry. LMW has recently completed the commissioning of a 30,000 spindles project at their Bela facility dedicated to processing Cotton, Viscose, and blends (P/C, P/V) applications. Concurrently, the next expansion project with 30,000 spindles at the same location is under supply for cotton and blends application.

Mr Basant Kumar Mohota, Chairman

M /s. Gimatex, a business conglomerate with a rich heritage of over 125 years (dates back to M/s. RSR Mohota Mills in the year 1898) is today a completely integrated textile facility from Ginning to Apparel (Ginning, Spinning, Weaving, Processing & Apparels).

In operation since 1996 with 25,000 spindles, today the company has grown significantly to a capacity of more than 2,00,000 spindles & 960 Airjet Spindles with modern production and testing facilities strategically distributed across Hinganghat, Wani and Bela cities of Maharashtra that deliver superior total value to the customers.

Mr Prashant Kumar Mohota,

Managing Director

“Our association with LMW is over three decades old. All our latest spinning projects are with 100% LMW machinery as we are highly satisfied with the performance and the other stated deliverables. Our Silver Jubilee was celebrated last year (2022) and Shri Sanjay Jayavarthanavelu, CMD, LMW was the Chief Guest for the event which reiterates the long-standing association between us”.

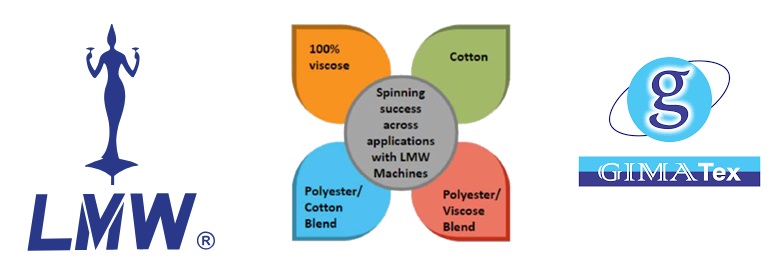

Versatile solutions compatible with a plethora of applications

The versatile smart series machines from LMW, compatible with a diverse range of raw materials, including regenerated fibers, are a testament to sustainability and circularity in the field of spinning. The commissioning of several units with 100% LMW machinery, processing a varied range of counts from 20’s to 40’s for Cotton, Blends (P/C, P/V) and 100% Synthetic (100% Viscose) applications stands as a testimony to the reliability and adaptability of LMW solution offerings in meeting the evolving production requirements of M/s. Gimatex.

LMW and M/s. Gimatex, enduring partnership thriving within an environment of mutual trust...

The state-of-the-art facility at Hinganghat houses 100 % LMW machines with 25000 spindles capacity for processing polyester and viscose applications (Grey and Dyed). The Airjet looms at the facility are also equipped with smart preparatory machines from LMW.

At the facility in Wani, two units are equipped with 100% LMW smart solutions for processing P/V, P/C and 100% Viscose application, operating with 11,000 spindles capacity each. The unit – 3 at this facility with 11,000 spindles capacity is equipped with state-of-the-art solutions from LMW for preparatory spinning and Unit - 4 is facilitated with LMW Smart Ring frames for 25,000 spindles capacity.

Smart Compact Ring frame LRJ 9/SXL

The installations (completed & ongoing), at Bela includes 4 Units wherein Unit - 1 & 2 are operating with A – Z state-of-the-art smart series machines from LMW at 30,912 spindles capacity for processing cotton and viscose materials. The machinery lineup at the Unit – 1 & 2 include,

| Department | Make / Model name | Unit - 1 | Unit - 2 |

| No. of units | No. of units | ||

| Application | Viscose &Poly-Viscose (DF Blend) | Cotton & Poly-Cotton (DF Blend) | |

| Blowroom | LMW Bale Plücker LA23/S | 1 | 1 |

| Card | LMW LC361 / LC363 | 11 | 16 |

| Breaker Draw Frame | LMW LDB3 (TD) | 5 | 2 |

| Finisher Draw Frame | LMW LDF3 S | 5 | 5 |

| Lap Former | LMW LH20 S | - | 2 |

| Comber | LMW LK69 S/M | - | 10 |

| Speed Frame | LMW LF 4280/SX | 4 (160 Spindles) | 5 (140 Spindles) |

| Compact Ring Frame | LMW LRJ 9/SXL | 6 (1632 Spindles) | 8 (1824 Spindles) |

| Ring Frame | LMW LR 9/SXL | 4 (1632 Spindles) | - |

The Unit – 3 & 4, at Bela facility with 30,912 spindles for processing cotton and blends application are currently under execution with end-to-end LMW solutions. The machinery lineup at this facility comprises of

| Department | Make / Model name | Unit - 3 | Unit - 4 |

| No. of units | No. of units | ||

| Application | (Blow Room) Blends | ||

| Blowroom | LMW Bale Plücker LA23/S with Auto Blend | 1 | 2 |

| Card | LMW LC361 / LC363 | 12 | 12 |

| Breaker Draw Frame | LMW LDB3 (SD) | 4 | 4 |

| Finisher Draw Frame | LMW LDF3 S | 6 | 6 |

| Speed Frame | LMW LF 4280/SX | 4 (180 Spindles) | 4 (180 Spindles) |

| Ring Frame | LMW LR 9/SXL | 10 (1632 spindles) | 10 (1632 spindles) |

The preparatory machines from LMW for cotton at this facility includes,

| Cotton Preparation | |

| Bale Plücker LA23/S | 1 |

| LMW LC363 | 12 |

| LMW LDB3 (SD) | 1 |

| LMW LDB3 (TD) | 1 |

| LMW LH20 S | 1 |

| LMW LK69 S/M | 6 |

Mr. Ashwani K. Gupta,

President (Spinning)

“In the last decade, LMW machines have reached greater levels in terms of technology. The latest smart series machines offer higher productivity and consistent quality. We are very much satisfied with the features offered across the machines and with the performance of Card, Draw frame, Speed frame and Suction Compact Spinning. The machines are performing well across various applications for a wide range of counts”.

The new generation machines from LMW are built to enable remote monitoring, remote diagnosis, and real-time data analysis to ensure spinning mills thereby making real-time spinning machinery data part of strategic decision-making process.

Additionally, LMW's machines are equipped with higher efficiency motors and reliable components, minimizing power consumption and contributing to sustainability goals. Real-time service support provided by LMW ensures longer machine uptime, enhancing reliability and the longevity of machine parts.

In the perspective of the Plant Technical Team, "Based on the hands-on experience in utilizing LMW machinery for over three decades, we could say that the most cost-effective spinning machinery that is available in the market is from LMW. The new range of machines, apart from their higher productivity and quality deliverables, offers high levels of user friendliness and easy maintenance”.

The enhanced productivity, coupled with consistent quality, power efficiency, reduced manpower requirements and costs, minimized waste, and various other advantages, guarantee a swift Return on Investment (ROI) for the deployed capital. This accelerated ROI is achieved within a short timeframe, empowering the customer to achieve success in their spinning endeavors.

LMW's Sustainable Smart Solutions for Spinning Success (4S), supported by a culture of innovation, empower mills with a technological and competitive advantage. This is achieved through mission-critical automation, real-time data, analytics from connected machines, compatibility with all applications, and reliable performance under diverse operating conditions.

info@lmwtmd.com

info@lmwtmd.com