Hindustan Textiles Success Story

Spinpact: A game-changer for Increased Productivity at Hindustan Textiles

Introduction

Offered with LMW Ring Frame LRJ9 series and as retrofit to earlier model, the SPINPACT is a cutting-edge unique suction compact system which renders higher productivity with superior quality with utmost ease of handling

N.Krishnakumar, Managing Director

Hindustan Corporation, Coimbatore

Hindustan Corporation, Coimbatore, India was the first venture of the Hindustan Group of Companies, established in the year 1958 by K Duraiswamy Naidu. Since inception, the business has been driven by the founder’s vision to meet the requirements of iron and steel in the industrial and construction sector. Hindustan Group, with a turnover of Rs 1,150 crore, is one of the largest traders of steel products in South India. The vision of the founder has been taken forward now by his successors, D Natarajan and his son N Krishnakumar. The group diversified into spinning in the year 1979 by establishing Hindustan Textiles with a capacity of 2,000 spindles.

N Krishnakumar took charge as Managing Director after graduating in Textile Engineering in the year 2002 and the business has been witnessing quick growth under his guidance with the total spindleage capacity reaching approximately 40,000 spindles as on date. The group has also invested in wind mill and solar plants for producing sustainable energy with a capacity of 18.5 MW. Hindustan Textiles decided to modernise one of their existing units to increase the productivity of 30’s Ne yarn which has a production capacity of approximately 10.3 tonnes per day. The old shorter ring frames were modernised with the latest long compact ring frame LRJ9/AX with in-built SPINPACT compact system.

To quote N Krishnakumar, “The immediate enhancement in productivity was evident with increase in yarn output reaching 13.5 tonnes per day, compared to 10.3 tonnes per day, which is 32% higher.

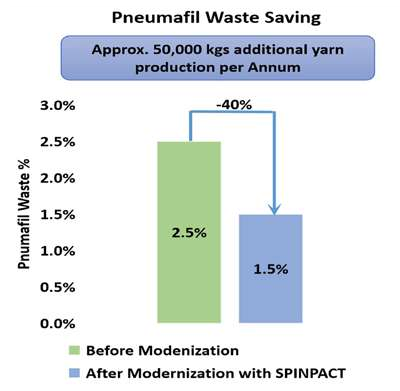

The Graph shows Pneumafil waste saving contributing to approximately 50,000 kgs additional yarn production per annum.

The increase in productivity has been achieved by optimisation of the following parameters

- TM reduction from 3.65 TM to 3.25 TM that contributes to 11% increase in productivity.

- Spindle speed increase along with addition of spindleage contributes to another 21% increase in productivity. The unique drafting construction in combination with high performance technological components HLLD spindles and CREDO+ rings helps in achieving higher productivity

- End-breakage reduction of 40% results in saving of 1% pneumafil waste. This is achieved with the unique spinning geometry used in SPINPACT for better twist insertion and twist flow.

The Spinpact Advantage

SPINPACT, the proven suction compact spinning system offers a compelling value proposition to the customers. Offered with LMW Ring Frame LRJ9 series and as retrofit to earlier model, the SPINPACT is a cutting-edge unique suction compact system which renders higher productivity with superior quality with utmost ease of handling. SPINPACT has unique spinning geometry which enables better twist insertion and twist flow. It is ideal to achieve the desired yarn qualities with higher yarn strength and lesser hairiness at higher productivity. The innovative nozzle design with extended compact slot length which is closer to front roller nip ensures perfect and prolonged compacting without fibre disturbance. LMW’s SPINPACT compact system is offered with DLS (direct loading system) for easy load adjustment for delivery roller, ensuring uniform load distribution for consistent quality.

All elements in SPINPACT are specially designed for increased reliability and ease of handling of the system. SPINPACT has a stand-alone suction unit with inverter control arrangement. The suction pressure can be adjusted based on requirement. A specially designed suction fan consumes less power while maintaining constant air pressure at every spindle. The suction unit can be mounted at head stock, end stock, wall or on the machine depending on the space availability which gives the user maximum flexibility. N Krishnakumar also shared that he closely follows developments in LMW’s product and their performance and confirmed that they are setting up a spinning mill with a capacity of 15,000 spindleage near Sathyamangalam, Erode consisting of all the latest ‘smart series’ machines including Card LC636 S, LDB3 S, LDF3 S, LF4280/SX and LRJ9/SX.

info@lmwtmd.com

info@lmwtmd.com