V.Thangavel & Sons Success Story

Driving Excellence in Cellulose Yarn Production: V.Thangavel & Sons Success with LMW’s Smart Machinery

Innovation and Sustainability at the Core: The Success Story of V. Thangavel & Sons Pvt Ltd (VTS)

V. Thangavel & Sons Pvt Ltd (VTS), a third-generation family-run enterprise, has built a strong legacy rooted in trust and reliability. Over the years, the company has achieved significant milestones in modernization and innovation by adopting LMW's advanced smart machinery for cellulose yarn production. With cutting-edge automation and digitalization, the company has enhanced productivity, improved quality standards, and excelled in producing superior high-strength yarns.

Founded with a visionary entrepreneurial spirit, VTS began its journey producing household textiles such as dhotis, lungis, and towels as FOX Brand Fabrics. Under the stewardship of three generations, the company has transitioned into a leading name in premium yarn manufacturing FOX Brand Yarns. This remarkable evolution was bolstered by their collaboration with LMW, whose state-of-the-art machinery and dedicated support played a crucial role in driving productivity and quality improvements.

With its legacy of trustworthiness, the company has established an impeccable reputation among textile players in Tamil Nadu. The adoption of LMW’s smart machinery has not only enabled them to remain at the forefront of the industry but also reinforced their commitment to innovation and sustainability, setting new benchmarks in the textile sector.

“LMW has played a pivotal role in our growth journey. Their support team visits our factory every three days, ensuring seamless operations. Their state-of-the-art machinery, coupled with 24/7 support for both our floor-level staff and management, truly distinguishes them. We are grateful to have such a reliable and innovative partner.”

- Mr. Karthikeyan Thangavel, Whole Time Director

Driving Technological Excellence in Cellulose Yarn Production

V. Thangavel & Sons has long been a leader in the textile industry, with a firm commitment to excellence in cellulose yarn production. With a daily output of 25 tons of 100% cellulosic yarn, the company specialises in Viscose, Micro Viscose, Bamboo, Eucalyptus, Sustainable Viscose Fibres like Liva Eco, Eco Vero, FSC, Modified Viscose like Modal, Micro Modal, Lyocell like Tencel Standard, LF, A100 & Excel, Recycled Cellulose like Liva Reviva, Circulose & Refibra and many more. Their dedication to eco-friendly materials is matched by an unwavering focus on quality and efficiency, ensuring that every product meets the highest industry standards.

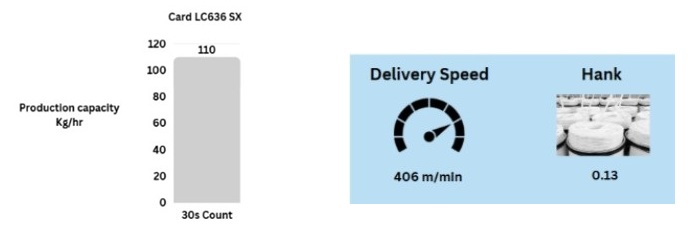

At the heart of their success is a blend of innovative technology and meticulous processes that prioritize consistency and minimize imperfections. The integration of LMW’s Smart machinery, including the Card LC636 SX with CDS attachment, has played a pivotal role in enhancing both productivity and yarn quality. This cutting-edge equipment allows VTS to consistently deliver premium yarns, reinforcing their position as a trusted name in the global textile market. They give all kinds of yarns like Ring, Ring Compact, Siro Compact, TFO, Slubs, High Twist and Airjet Yarns

Strategic Collaboration with LMW: A Path to Excellence

LMW has played a crucial role in the growth story of V.Thangavel & Sons by equipping their facility with our cutting-edge machinery. Today, they are equipped with Smart Machinery of LMW which are Card with CDS attachment, Drawframes with Autoleveller and Non Autoleveller, and SPINPACT with SIRO Compact attachment. These machines have delivered unparalleled performance, enabling the company to achieve remarkable efficiency and quality.

| V.Thangavel & Sons Pvt Ltd | |

| Department | Model |

| LMW Blowroom | LA21 |

| LMW Card | LC363 |

| LC636 S | |

| LC636 SX | |

| LMW Draw Frame (Breaker) | LD2 |

| LDB3 | |

| LDF3 | |

| LMW Draw Frame (Finisher) | LDF3 S |

| LMW Speed Frame | LF 4200/A |

| LF 4280/A | |

| LMW Ring Frame | LRJ 9/AXL |

| LRJ 9/SXL | |

Mr. Karthikeyan Thangavel shared his thoughts, stating, “LMW’s training programs are truly remarkable, benefiting not just executives but the entire industry. I dream of an LMW School of Excellence to educate and empower entrepreneurs with knowledge on machinery, yarn, and fabric applications.”

Expanding Horizons: Market Reach and Future Plans

V. Thangavel & Sons serves a wide array of domestic markets, supplying high-quality yarn to major textile hubs such as Surat, Mumbai, Erode, Salem, Tirupur, Palladam, Somanur, Coimbatore, Madurai, Ludhiana, Delhi and Kolkata. Looking ahead, the company has ambitious plans to broaden its footprint by extending its reach to new regions, including Uttar Pradesh, with a particular focus on areas like Panipat and Varanasi.

Future Goals: Innovation and Expansion

V. Thangavel & Sons has set ambitious future goals, including the blending of Poly cellulose and Cotton cellulose yarns to create innovative products. The company is also planning significant investments in weaving and knitting facilities to further enhance value addition. As part of its growth strategy, V. Thangavel & Sons aims to double its spinning capacity and install 100 looms, positioning itself for long-term diversification and market leadership.

Commitment to Sustainability and Innovation

Sustainability is at the heart of V. Thangavel & Sons’ operations as a 100% cellulosic yarn producer. By utilizing eco-friendly fibers and incorporating LMW’s energy-efficient machinery, the company reduces its environmental footprint while upholding high-quality standards. Additionally, V. Thangavel & Sons primarily sources its energy from renewable sources, reinforcing its commitment to both sustainability and innovation.

info@lmwtmd.com

info@lmwtmd.com