Articles

Card LC636 SX with CDS: Setting New Benchmarks in Productivity and Quality

“Excellence in Every Fiber & Flexibility in Various Applications”

LMW card LC636 SX with CDS stands as the pinnacle of advanced and futuristic carding technology with an integrated draw frame, offering exceptional and unique flexibility across a range of applications including spinning, OE (Open End), and recycling processes. This is particularly vital in the spinning segments. To spin success in this intense globally competitive environment, it’s crucial for spinners to enhance their brand reputation by producing high-value products with benchmark quality.

Versatility in Various Applications:

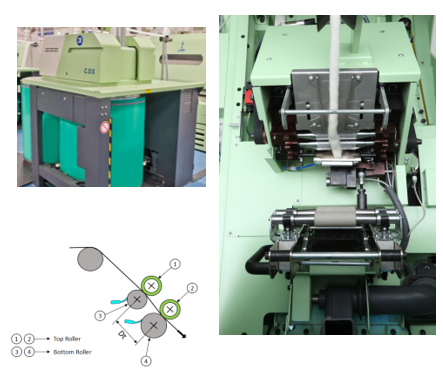

The LC636 SX with CDS stands at the forefront of spinning innovation, boasting exceptional sustainability and reliability in processing a diverse range of fibers while preserving their unique properties. At the core of its superior functionality is its advanced carding action, which is pivotal in delivering high-quality yarn consistently. The LC636 with CDS carding machines are elevated to new heights of performance with the unique 2-over-2 drafting system combined with a robust pneumatic loading mechanism and precisely synchronized servo drive control. This advanced system ensures accurate auto-leveling functions, significantly enhancing sliver quality.

Cotton: A unique process in cotton fiber separation and cleaning is expertly managed by the advanced system of the LC636 SX with CDS technology. This innovative machine employs a gentle carding action, ensuring precise fiber-to-fiber separation and thorough cleaning. The result is high-quality cotton fibers that retain their integrity, ready for further processing.

Re-cycle: In the challenging recycling process, where controlling short fiber levels is essential, the LC636 SX with CDS technology excels. Utilizing state-of-the-art systems and gentle carding action, it ensures superior yarn quality and sustainability, delivering exceptional results consistently.

Synthetic: The LC636 SX with CDS features and robust components that ensure proper fiber separation with gentle handling, delivering benchmark sliver quality.

Blends: Processing different types of material and fibers characters will be a pivotal role in carding action where LC636 SX with CDS advanced system and control units delivers exceptional results. The LC636 SX not only meets the highest standards of yarn quality but also enhances operational efficiency, solidifying its reputation as the premier choice for achieving excellence in the yarn manufacturing process.

LC636 SX with CDS Technology - User friendly & Easy Maintenance:

Patented replaceable shoe arrangement: Less maintenance cost, Easy to replace & Accurate setting between flat & cylinder. LMW patented flat design maintaining flat concavity lower than competition which delivers better setting gap to achieve better quality with consistency.

Five level sensor and arcual combing: Robust and dynamic feed roller with five level sensor and arcual combing segment with precise nipping distance setting enhance the smooth fiber opening with minimum waste extraction level than competitor.

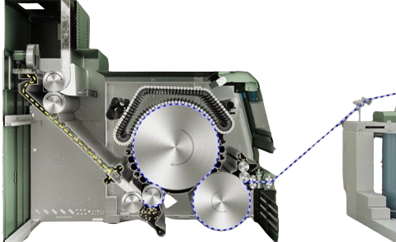

Active Cylinder area (ACA) - 3.95 m2: Technological elements occupies 82% of the cylinder surface ensure better fiber separation and NRE%.

Active Carding Area” (AKA) 1.95m2: High reliability due to robust metallurgy of cylinder and side frames and optimized cylinder diameter controls heat generation and thermal expansion while running. It ensures uniform setting in “Active Carding Area” (AKA) 1.95m2.

Flexibility in maintenance & Cost Effective Operation:

The LC636 SX advanced engineered features and reliable technological components, driving the system's success in long-term operations with minimal maintenance costs and power savings. Its sophisticated power-saving mechanisms significantly reduce energy consumption, while innovative waste control systems minimize material loss, optimizing resource utilization.

Our studies across various applications have demonstrated that LMW carding machines offer exceptional reliability and cost savings, with maintenance costs up to 30% lower than competitors' latest models and power savings (UKG) up to 15%. This proven track record highlights the card LC636 SX's superior performance with CDS system, making it a cost-effective and dependable choice for modern spinning industry.

The LC636 SX with CDS enhances realization rates by maximizing fiber utilization, ensuring superior performance. Its advanced carding technology delivers uniform fiber separation, minimal neps, and improved NRE%, consistently achieving benchmark quality and productivity. This state-of-the-art machine elevates yarn production standards and sets new benchmarks in sustainability and operational efficiency.

LC636 SX with CDS & Fix-Fil Technology:

The CDS (Card with Drafting System) is designed to deliver high-precision sliver quality consistently through a user-friendly digital-controlled auto-leveling operation. This system simplifies the process, making it easier to use while maintaining precision in output.

The CDS System offers exceptional flexibility, adept at processing a diverse array of materials, encompassing both natural and synthetic fibers. Its versatile design ensures seamless adaptation to different manufacturing and application requirements, making it a preferred choice across multiple spinning / OE - Recycle segments. Furthermore, the CDS system has established a stellar reputation for reliability and efficiency, consistently delivering outstanding performance that meets the exacting standards of our numerous esteemed customers.

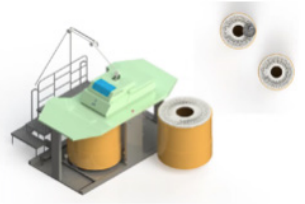

Additionally, the optional Fix-Fil coiler with an auto-piecing feature represents a valuable technological upgrade. This innovation reduces piecing time by up to 50% and boosts productivity by approximately 2%. The synergy of these core technologies underscores a significant leap in operational efficiency and output quality, setting a new benchmark.

CDS - Application & Performance:

The LC636 SX with CDS systems are delivering outstanding performance, consistently producing high-quality output. The synergy between the LC636 SX and CDS technologies results in exceptional performance across various spinning processes, including Spinning, OE-recycle, and Air Jet Spinning (Vortex). Particularly in recycling, the CDS system plays a crucial role in enhancing sliver quality. The primary challenge in recycling is controlling short fibers and maintaining uniform sliver consistency. With the advanced technology and precise servo control systems of the LC636 SX with CDS, benchmark results are achieved consistently throughout the process. This ensures superior sliver quality and uniformity, setting a new standard in the industry.

Mill Network system - “SPINCONNECT”:

LMW Spin connect is a robust web-based monitoring and control application designed to seamlessly integrate and oversee processes from Blow room to Winder within industrial settings. It offers highly reliable data analytic capabilities, empowering users to derive actionable insights and make informed decisions swiftly. By facilitating comprehensive monitoring and analysis across the production line, Spin connect enhances operational efficiency and productivity, ensuring optimized performance and quality throughout the manufacturing process.

info@lmwtmd.com

info@lmwtmd.com