Articles

Revolutionizing Power saving with Higher productivity & Benchmark Quality

LMW’s Ring Frame LRJ 9/SX Series

LMW’S Smart Ring spinning machine LRJ 9/SX series is built with superlative technology to spin high quality yarn. Compatible for industry 4.0 standards, this advanced new age machine is flexible and engineered with smart features which ensures, high productivity, benchmark quality, lower energy consumption and sustainable features for modern textile industry.

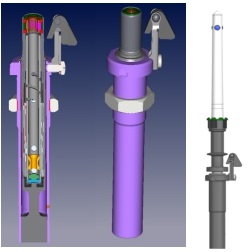

Higher productivity and Lower energy consumption with LMW LRJ 9/SX series - Most versatile Ring Spinning Technology with suction compact system Spinpact

- Hi-tech unique suction compacting system with ease of handling

- Unique top suction arrangements and Uni-Compact suction nozzle made up of special aluminium alloy for eight spindles

- Special spinning angle for enhanced performance and lower power consumption

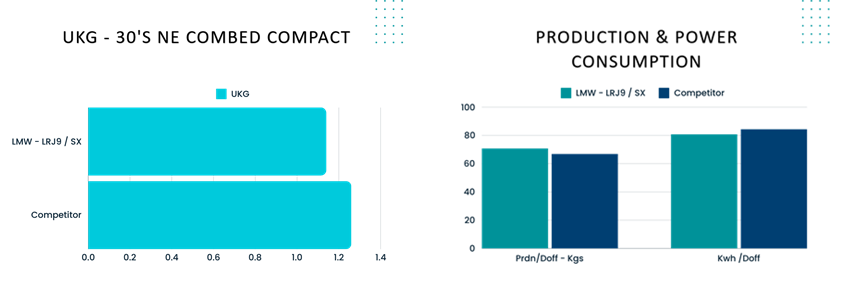

In a recent comparison at a Turkish spinning mill, the LRJ 9/SX series suction compact spinning machine showed a significant 10.50% reduction in energy consumption compared to Ring Frames of other manufacturers. This result highlights the efficiency and eco-friendly nature of the LRJ 9/SX series, making it a promising option for spinning mills looking to reduce their energy usage and operating costs. Also, it benefits from annual savings of around 48,000 USD for 10 machines with 1632 spindles.

LMW's smart ring spinning technology with spinpact system has once again been proven to be the global benchmark for productivity and machine performance. This energy comparison study reaffirms the efficiency and effectiveness of this innovative technology, showcasing its superiority in terms of output and operational excellence.

Power study comparison data

| Machine Model | LRJ 9/SX | Competitor | |

|---|---|---|---|

| No. of Spindles | 1632 | 1632 | |

| Count | Ne | 30 /1 Combed compact | 30 /1 Combed compact |

| Spindle speed in RPM | Maximum | 19500 | 19500 |

| Average | 18500 | 18500 | |

| TPI | 19.76 | 19.76 | |

| Tube length/Ring Dia (mm) | 190 / 38 | 190 / 38 | |

| UKG | 1.14 | 1.26 | |

| Difference in % | 10.53 | ||

| Remarks | 10.53 % lesser power consumption in LRJ 9/SX | ||

The LRJ 9/SX series machines come equipped with an energy consumption monitoring system. This system provides detailed insights into power consumption, allowing for better understanding and control. Moreover, its flexibility to connect with the SPINCONNECT system enhances data integration and monitoring capabilities. This setup enables efficient energy management and optimization for enhanced operational performance.

LRJ 9/SX Series Added Technology for Energy efficient spinning operation

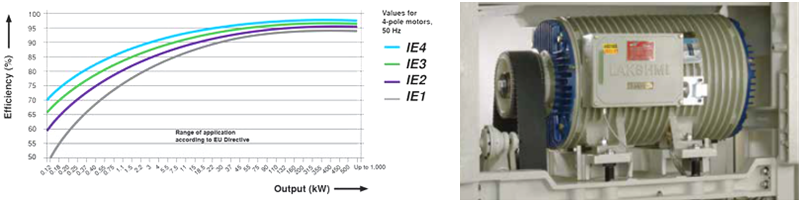

IE4 INX-OPTI Energy Efficient Main Motor: IE4 motors are designed with superior materials and durable features, leading to smoother operation and reduced maintenance needs. The use of high-quality components ensures a longer lifespan and more reliable performance over time. These motors are built to withstand wear and tear, providing a cost-effective solution for industries requiring continuous and efficient operation.

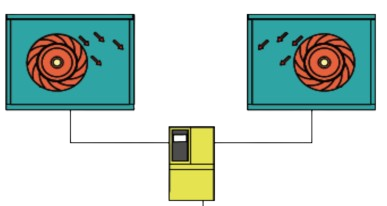

Pnuemafil suction with Smart control system

The inverter's ability to adjust the pneumafil suction fan speed based on suction needs during regular machine operation is a significant advantage. The precise control over acceleration and deceleration provided by the inverter enhances the efficiency of the system. This fine-tuned control not only optimizes performance but also contributes to energy savings, making the overall operation smoother and more cost-effective.

The new Inbuilt smart suction control system adjusts suction pressure based on yarn winding length, optimizing machine performance. Setting the right suction pressure levels can lead to significant power savings, making it a beneficial feature for efficient operation.

Adjusting OHTC Running Utilization for Energy Efficiency

By adjusting the number of traveling cycles per hour or the parking cum standstill time, operators can optimize the performance of OHTC machines. This smart function ensures contributing to power savings. Fine-tuning the OHTC running utilization based on machine performance can result in significant energy savings during operations.

High performance Credo + Rings

The LMW Credo + Rings have shown consistent performance in various spinning mills for different materials. Their precise profile geometry leads to shorter running periods, enhancing productivity. This proven track record makes them a reliable choice for achieving high efficiency in spinning operations. The credo + Rings precise profile geometry shortens running periods and increases micro hardness for extended ring life. This results in less friction between traveler and ring surface, leading to energy-efficient performance and higher productivity.

Excellent Performance with Energy Efficient Silent Spindles

The Ring Frame LRJ 9/SX Series is equipped with HLLD/HLED spindles known for their low noise and vibration levels. This feature contributes to enhanced performance at higher spindle speeds. Additionally, these spindles guarantee energy-efficient operation, making them a reliable choice for benchmark productivity in industrial settings. The noise level is reduced upto 5dB.

The LRJ 9/SX smart Ring spinning technology has been a game-changer in the textile industry. Its advanced features cater to the evolving needs of end users. With limitless success stories, this machine is paving the way for the future of modern textile production. Its design reflects a commitment to innovation and efficiency, making it a key player in shaping the textile industry's future landscape.

info@lmwtmd.com

info@lmwtmd.com