Articles

LMW's Smart Ring Frame LRJ 9/SXL: Pioneering the Next Generation Technology in Spinning

LMW's LRJ 9/SXL Ring Frame, equipped with cutting-edge modern technology, is a great choice for our valued customers. This innovative system aims to revolutionize the spinning industry, ensuring efficiency and quality. "Together we spin success" embodies the collaborative effort between LMW and its customers to achieve excellence in their textile operations.

The LRJ 9/SXL model’s advanced features are designed to deliver exceptional results to its customers. These meticulously developed features have been crafted to deliver high performance and reliability. They are tailored to meet the demands of all valuable users. With a focus on precision, efficiency, and innovation, the LRJ 9/SXL model sets a new standard in delivering benchmark results that exceed expectations.

Unparalleled Performance and Reliability with LMW LRJ 9/SXL :

This advanced system excels not only in productivity and quality but also in energy efficiency, maintenance cost, and user-friendly operation. Its proven track record highlights its ability to provide high flexibility and ease of use while minimizing energy consumption and maintenance expenses. This combination of features makes it a top choice for those looking for a reliable and efficient system. Consistent delivery ensures reliability, guaranteeing a seamless experience for users.

Energy Efficient System with advanced components with LMW LRJ 9/SXL :

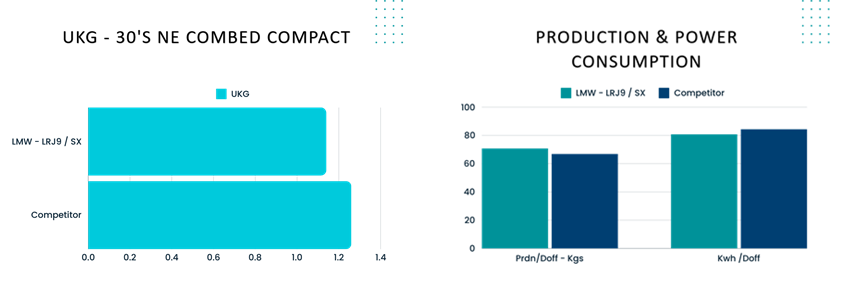

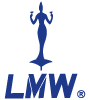

The LMW LRJ 9/SXL stands out with its impressive track record of achieving up to 10% power savings (UKG) when compared to the latest ring frame models from competitors. This energy efficiency not only leads to cost savings but also contributes to environmental sustainability. The ability to reduce power consumption by such a significant margin showcases the advanced technology and engineering behind the LMW LRJ 9/SXL, making it a compelling choice for those looking to optimize energy usage in their operations.

The enriched engineered technological components like HLLD/HLED silent spindles, higher polished surface finish credo+ rings, energy-efficient IE4 Opti-power motors and inverter- controlled suction system drive power savings. These advanced parts are designed to provide improved performance and efficiency in various applications. By combining these technological parts effectively, we can deliver the results promised to our valued customers. This synergy ensures that our products and services meet their expectations and needs. It is crucial to integrate these components seamlessly to provide a seamless and satisfactory experience for our customers.

The use of HLLD/HLED technology in spindles can lead to higher speeds of up to 30,000 RPM mechanically with minimal friction and vibration levels. This results in energy-efficient operation, as the reduced friction helps in cutting down on energy consumption while maintaining a quiet working environment. The noise level is reduced upto 5dB.

Enhanced Productivity and Cost Efficiency with LMW LRJ 9/SXL :

The servo-controlled drafting drive system with robust technological components is crucial for minimizing downtime and boosting productivity. Spinpact process with a yarn count of 30's Ne producing around 510 tons annually with 1824 spindle machine, the reliability and efficiency of the system are paramount. By ensuring smooth operation and minimal maintenance requirements, this setup can significantly enhance overall output and operational efficiency in the spinning industry. By opting for LRJ 9/SXL ring frame for high volume spindle project, you can achieve a significant up to 28% reduction in annual maintenance costs compared to competitors. This remarkable cost-saving advantage not only enhances operational efficiency but also contributes to long-term savings for the project.

Reduced Footprint @ LMW LRJ 9/SXL 65mm Gauge / 720CC Angle Technology:

LMW has developed an innovative system for the ring frame process featuring a 65 mm gauge and intelligently designed spinning geometry (720CC) and 41 mm quality cradle. This advanced system leads to power savings, productivity improvements, space efficiency, enhanced yarn quality, and uninterrupted machine performance.

Our state-of-the-art technology offers several key benefits, as demonstrated by our successful partnership with a long-standing customer in South India. With LMW's system, customer achieved bench marking productivity of 80 GPS for 68’s Ne with a 20% improvement in IPI quality levels, and a 25% reduction in end breakage rates and accommodating 8% more spindles.

LMW's precisely engineered smart products consistently deliver exceptional results fulfilling customer expectations.

Maximizing Efficiency: Enhancing Consistency Through LMW's Advanced Automation System

LMW's LRJ 9/SXL advanced automation system and engineered solution brings a new level of efficiency and precision to the spinning industry. This innovative system is well-received by LMW customers due to its ability to streamline production processes and deliver high-quality results. With LMW's cutting-edge technology, spinning factories are able to boost productivity and meet the demands of a rapidly evolving market.

The combination of a robust dynamic drive system and precise pneumatic control for tube loading can greatly enhance the efficiency of the ring frame auto doffer. This setup maximizes machinery utilization by ensuring seamless and accurate operations. The robust doffer drive system provides the necessary energy for smooth functioning, while the precise pneumatic control guarantees efficient tube loading, streamlining the overall process. This integration improves performance / machinery utilization and productivity, making it a valuable addition to the machinery setup.

The YBS (Yarn Break Sensor) is a valuable innovation in ring frame operation. It enhances operators' monitoring efficiency and reduces pneumafil waste, ultimately boosting productivity. This technology streamlines the detection of yarn breaks, aiding in quicker responses and minimizing material wastage. Such advancements not only optimize operational processes but also contribute to cost-effectiveness and sustainable production practices.

By adopting the innovative system of Ring Frame Auto piecer (RAP) and YBS, there is potential to reduce upto 60% of manpower in ring frame operations. The RAP functions like a human piecing system, leading to reduction in waste and ultimately higher productivity.

Implementing LMW's advanced automated system with energy-efficient technological components and the value-addition technology

Spinpact can greatly enhance productivity. The combination of these cutting-edge technologies ensures optimized performance and resource utilization, leading to increased productivity and output.

Mill Network system - “SPINCONNECT”:

LMW Spinconnect is a robust web-based monitoring and control application designed to seamlessly integrate and oversee processes from Blow room to Winder within industrial settings. It offers highly reliable data analytic capabilities, empowering users to derive actionable insights and make informed decisions swiftly. By facilitating comprehensive monitoring and analysis across the production line, Spinconnect enhances operational efficiency and productivity, ensuring optimized performance and quality throughout the manufacturing process.

OEM and Retrofit option for versatile compact Attachment :

LMW's Spinpact suction compact spinning system is an innovative technology that offers exceptional value by enhancing productivity and ensuring superior yarn quality. This advanced system integrates suction compact spinning, setting new benchmarks in the industry. It streamlines the spinning process, resulting in higher productivity levels and top-notch yarn quality. The Spinpact system is a game-changer in the textile industry, providing manufacturers with a competitive edge in today's market.

Spinpact as Retrofit is available for all LMW’s Ring Frame

Spinpact Suction Compact System and SIRO Retrofit

Spinpact suction compact system and SIRO offer a seamless modernization solution for all LMW's ring frame machines. This retrofit can be easily installed and upgraded, providing a boost to spinning technology. The combination of these systems ensures enhanced performance and efficiency, making them a valuable addition to any spinning mill looking to stay competitive in the modern textile industry.

info@lmwtmd.com

info@lmwtmd.com