Blog

LMW leading the way in Recycled Fiber Processing for the Spinning Industry

Introduction

As the textile industry embraces eco-conscious future, the shift toward circularity has become a defining priority. As global demands for eco-friendly practices rise, LMW leads this transformation with its innovative solutions in recycled fiber processing. By integrating sustainability, performance, and cutting-edge technology, LMW empowers to minimize environmental impact while enhancing productivity and meeting market demands for sustainable textiles.

LMW RESPIN Impact

LMW RESPIN is a commitment to a sustainable future. It is designed to integrate sustainability, innovation, and performance, enabling textile manufacturers to adopt eco-friendly practices. Various raw materials / feed materials are used in the recycled process. Virgin material of cotton and polyester are added as per the end product requirements.

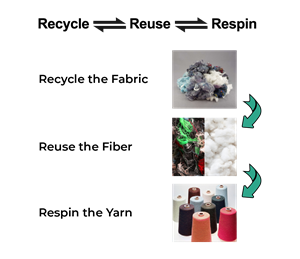

“Recycle, Reuse, Respin”: LMW’s Mantra for a Greener Future

LMW’s “Recycle, Reuse, Respin,” underscores its mission to transform the textile industry. By turning waste into value, LMW helps manufacturers contribute positively to the planet while remaining competitive in the market. This approach not only supports environmental sustainability but also addresses the growing consumer demand for eco-friendly products.

LMW's Smart Series: Leading the Way in Recycled Fiber Processing

LMW's Smart Series machines are specifically engineered for mechanical recycling, making them ideal for processing a variety of recycled materials. These machines are not only efficient but also versatile, capable of handling different types of fibers with ease.

The Process: From Waste to Yarn

LMW’s solutions are built around a systematic approach to recycling. The process begins with waste classification, where raw materials are sorted based on the final product’s requirements. The materials can include:

- Fabric cuttings and hosiery waste

- Post-consumer used and unused textiles

- Recycled polyester and PET fibers

These classified materials are then processed through several stages, each designed to optimize resource use while ensuring minimal waste:

- Opening and Cleaning: Machinery like the Mixing Bale Opener (MBO) and Swift Floc ensure efficient fiber opening and removal of impurities, providing a clean base for further processing.

- Blending and Mixing: LMW’s Auto Blend LA10 system achieves a high degree of blending accuracy, allowing up to four assortments to be processed simultaneously with a throughput of 1,600 kg/hr.

- Carding: The Card LC 363/361 and Drafting Systems deliver uniform sliver quality, essential for producing regenerated yarns with high consistency.

- Spinning: The Smart Ring Frame series facilitates the creation of high-quality yarn from recycled fibers, offering flexibility to produce a wide range of counts.

Advantages of LMW’s Smart Machinery

- LMW’s Smart Machinery offers several distinct advantages for manufacturers venturing into recycled fiber processing:

- Energy Efficiency: Smart automation minimizes power consumption while maintaining high production levels.

- Versatility: The ability to process varied materials makes LMW’s systems ideal for meeting dynamic market demands.

- Sustainability-Driven Design: Each machine is engineered to minimize waste and maximize output, reflecting LMW’s commitment to the environment.

The Road Ahead

As the textile industry continues to evolve, recycling will play an increasingly critical role. LMW are not only shaping the future of textile manufacturing but also setting new benchmarks for sustainability. With its cutting-edge technology and unwavering commitment to circularity, LMW is a guiding light for an industry striving to reduce its environmental footprint.

By choosing LMW’s solutions, textile producers can embrace a sustainable future and lead the way in responsible textile production. Together, let’s recycle, reuse, and respin to create a better tomorrow.

info@lmwtmd.com

info@lmwtmd.com